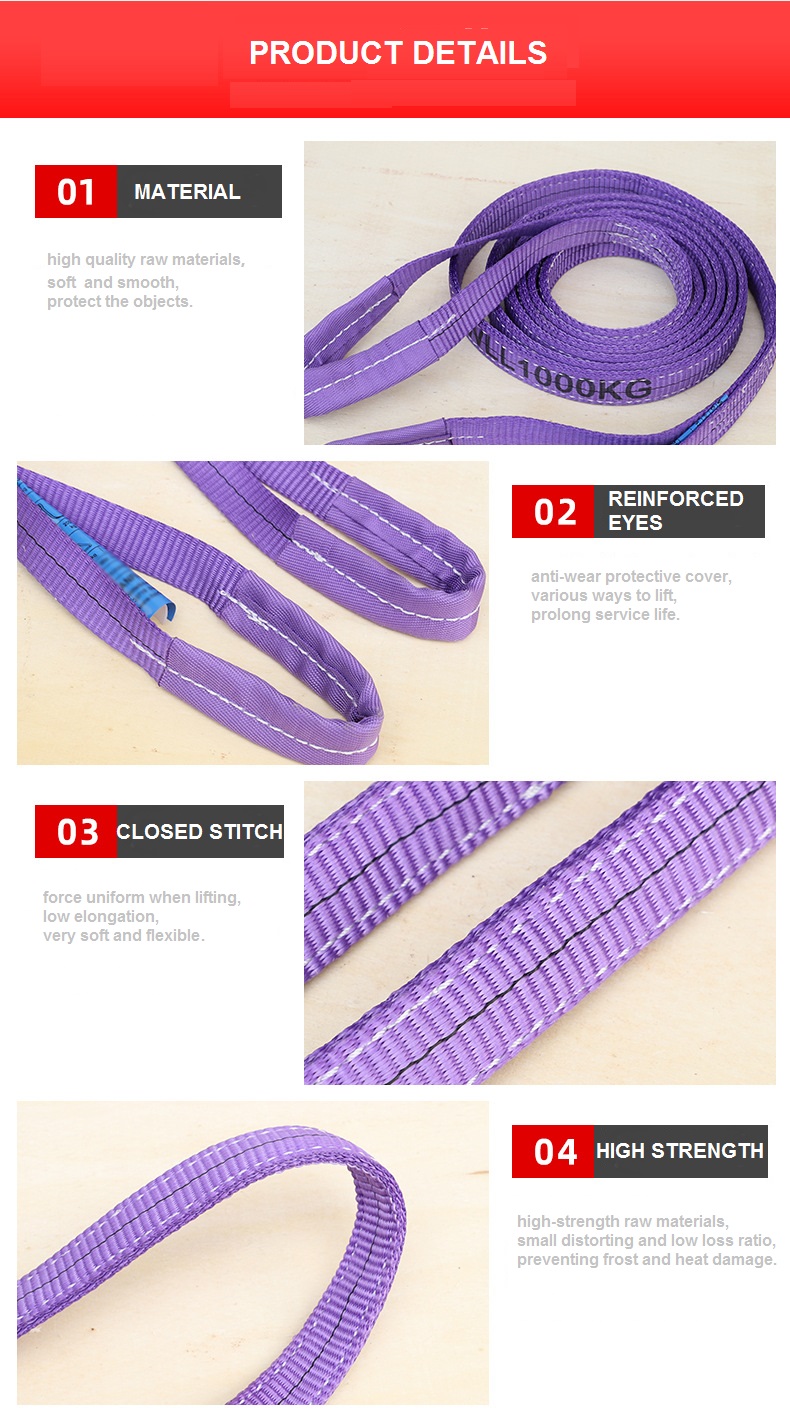

Polyester Duplex Webbing Sling are versatile as they can be used in choker, vertical, or basket hitches.Polyester fabric has low elongation, so it’s better able to hold the load without the risk of shocking.OEM service is also available.

Item No :

WS7100Order(MOQ) :

1Payment :

30% deposit, 70% pay after receiving BL copyProduct Origin :

ChinaColor :

VioletShipping Port :

Nanjing/ShanghaiLead Time :

15-45daysBrand :

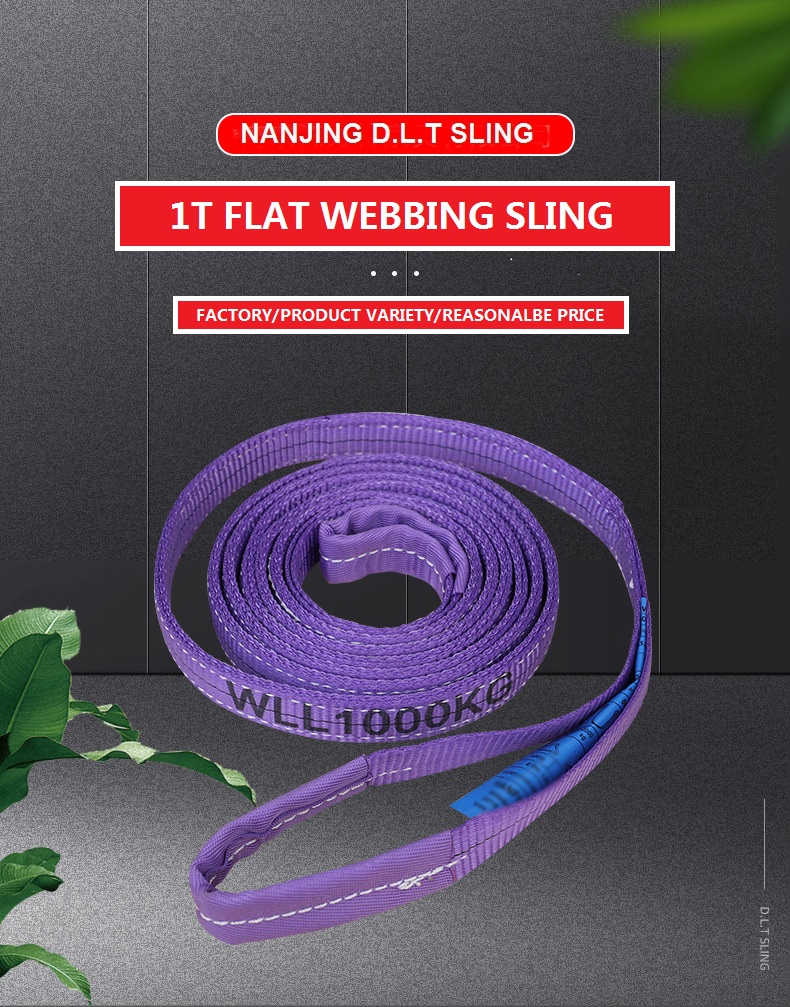

D.L.T SLINGPolyester Duplex Webbing Sling SF7

The duplex sling must be both long enough and strong enough for the load and the slinging method. Apply the mode factor for the slinging method. For use at temperatures exceeding 80°C or below 0°C refer to the suppliers instructions. If the slings are used in multi-leg arrangement the angle formed between the legs should not be less than 30° or greater than 90°. If abrasion, heat generated by friction or cutting from edges or corners are likely, select a sling fitted with protective sleeves and/or use suitable packing.

|

Type |

1T FLAT WEBBING SLING |

|

Brand Name |

D. L.T SLING |

|

Material |

100% PES |

|

Width |

50mm |

|

Length |

Can be customized as require |

|

W.L.L |

1ton/1000kg |

|

Safety Factor |

5:1,6:1,7:1,8:1 all available |

|

Layer |

two ply |

|

Color |

violet |

|

Standard |

EN1492-1 |

|

Certificate |

ISO9001, CE, TUV-GS, etc. |

|

Place of Origin |

Nanjing,Jiangsu, China |

|

Packing |

plastic bag, carton and pallet |

Using Belt Slings Safely

Do not attempt lifting operations unless you understand the use of the equipment, the slinging procedures and themode factors to be applied. Do not use defective slings or accessories. Check the correct engagement with fittingsand appliances, ensure smooth radii are formed, do not twist or cross slings and do not overcrowd fittings. Position the sling so that the load is uniformly spread over its width. Position the bight for a choke lift at the natural (120°) angle to prevent friction being generated. Ensure that stitching is in the standing part of the sling away from hooks and other fittings. Take the load steadily and avoid shock loads. Do not leave suspended loads unattended. In an emergency cordon off the area.

In-service Inspection and Maintenance

Maintenance requirements are minimal. Belt slings may be cleaned with clear water. Remember weak chemical solutions will become increasingly stronger by evaporation. Regularly inspect belt slings and, in the event of the following defects, refer the sling to a Competent Person for thorough examination: illegible markings; damaged, chaffed or cut webbing; damaged or loose stitching; heat damage; burns; chemical damage; solar degradation; damaged or deformed end fittings.

FAQ

We are honored to offer you free samples, but clients are expected to pay for the courier costs.

Q3: What are your payment terms?

Delivery time will be within 60 days since the PI is confirmed and we receive the advance payment.