When it comes to lifting heavy loads, choosing the right type of sling is crucial for ensuring safety and efficiency. Two common options available in the market are webbing slings and steel slings. Each type has its own set of advantages and considerations that need to be taken into account. In this blog post, we will compare and contrast webbing slings and steel slings, analyzing their strengths, limitations, and suitability for different lifting operations. By understanding the differences between these two options, you can make an informed decision and select the best sling for your specific needs.

Steel slings are known for their exceptional strength and high load-carrying capacity. They are often preferred for lifting extremely heavy loads or in applications where durability is paramount. Webbing slings, on the other hand, have lower load-carrying capacities but offer excellent flexibility and versatility. Their strength lies in their ability to conform to the shape of the load, providing secure and balanced lifting.

Webbing slings are lightweight and easy to handle, making them convenient for various lifting tasks. They can be easily adjusted and maneuvered into position. Steel slings, while strong, are heavier and less flexible. They require more effort to handle and may require additional equipment like hooks or shackles for attachment. The choice between the two will depend on the specific requirements and ease of use in your operation.

Steel slings are resistant to high temperatures, making them suitable for lifting operations in extreme heat or fire-prone environments. Webbing slings, typically made from synthetic materials like polyester, may have limitations when exposed to extreme temperatures and chemicals. It's important to consider the environmental conditions of your operation and choose a sling that can withstand those challenges.

Webbing slings are less prone to causing damage to lifted objects since they have softer surfaces compared to steel slings. However, they are more susceptible to wear and tear, especially when used in rigorous or abrasive environments. Steel slings, while durable, may cause scratches or dents on the load. Regular inspection and maintenance are essential for both types of slings to ensure their longevity and safe operation.

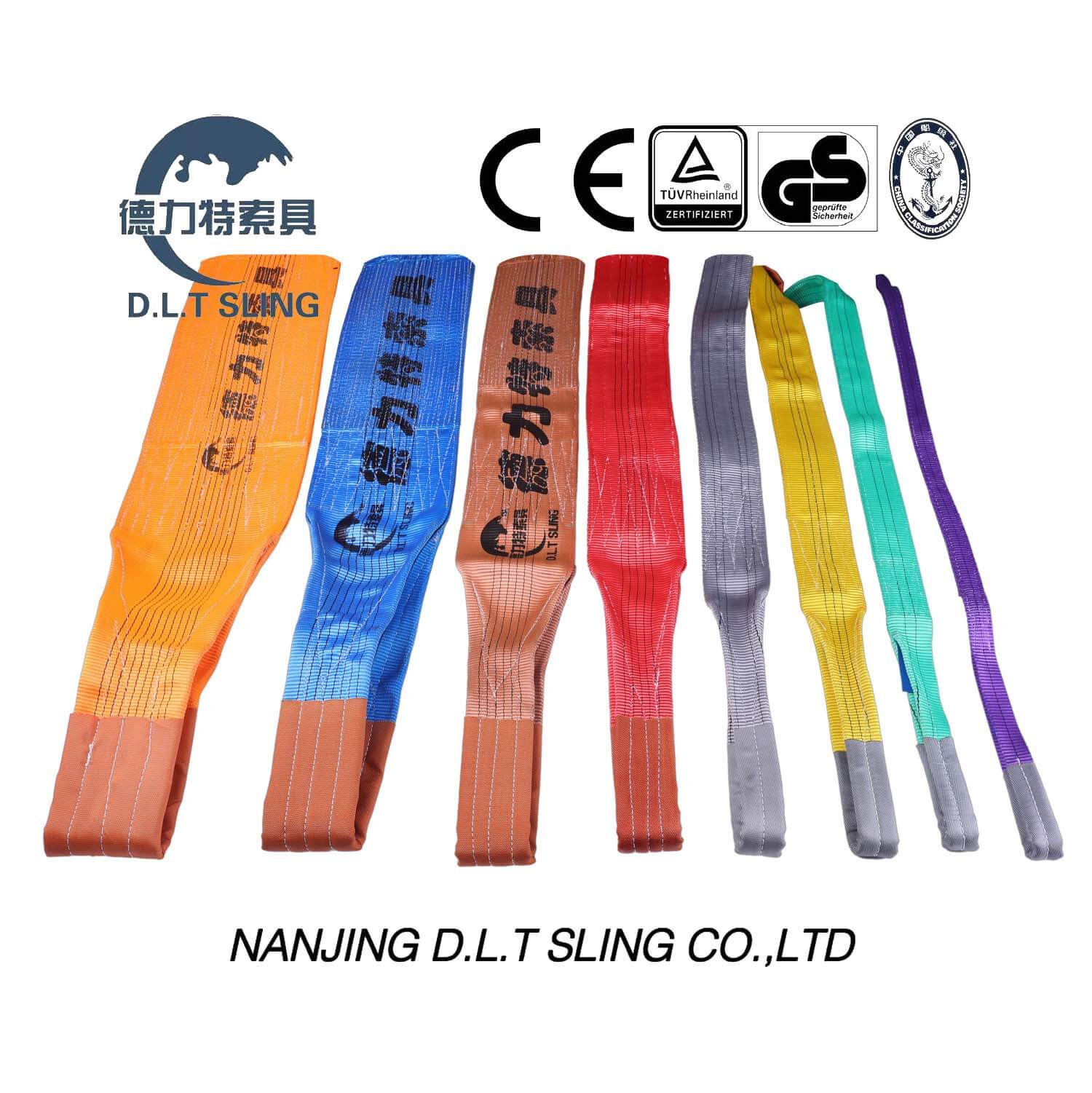

Webbing slings are generally more cost-effective compared to steel slings, making them a preferred choice for many operations. They are readily available and offer a good balance of performance and affordability. Steel slings, on the other hand, have higher upfront costs but may be more economical in the long run due to their durability and longer lifespan.

Choosing between webbing slings and steel slings requires careful consideration of your specific lifting requirements, environmental conditions, and budgetary constraints. Both options have their own strengths and limitations. Webbing slings offer flexibility, ease of use, and cost-effectiveness, while steel slings provide superior strength and durability. Ultimately, the best choice will depend on the unique needs of your operation. By assessing these factors, you can make an informed decision and ensure safe and efficient lifting.